EU+GMP+第一章药物质量体系+草案

VIP免费

Page 1 of 9

Chapter 1: Pharmaceutical Quality System 第一章:药物质量体系

Consultation Document 征求意见草案

Reasons for changes: The GMP/GDP Inspectors Working Group and the PIC/S Committee

jointly recommended to amend the text of Chapter 1 in order to reflect the changes

introduced in ICH Q9(R1) on Quality Risk Management.

修订原因: GMP/GDP检查工作组和PIC/S委员会共同建议修订第一章内容,反映ICH Q9(R1)质

量风险管理中引入的变化。

Page 2 of 9

Principle

The holder of a Manufacturing Authorisation must manufacture medicinal products so

as to ensure that they are fit for their intended use, comply with the requirements of the

Marketing Authorisation or Clinical Trial Authorisation, as appropriate and do not place

patients at risk due to inadequate safety, quality or efficacy. The attainment of this

quality objective is the responsibility of senior management and requires the

participation and commitment by staff in many different departments and at all levels

within the company, by the company’s suppliers and by its distributors. To achieve this

quality objective reliably there must be a comprehensively designed and correctly

implemented Pharmaceutical Quality System1 incorporating Good Manufacturing

Practice and Quality Risk Management. It should be fully documented and its

effectiveness monitored.

A proactive approach to quality risk management is of strategic importance in achieving 1

an effective pharmaceutical quality system, in facilitating continual improvement and 2

in enabling informed and timely decisions throughout the product lifecycle. 3

以主动方式进行

质量风险管理在

达成有效的药物

质量体系、促进

持续改进和药品

生命周期中及时

主动做出知情决

策中有着战略重

要性。

All parts of the Pharmaceutical Quality System should be adequately resourced with

competent personnel, and suitable and sufficient premises, equipment and facilities.

There are additional legal responsibilities for the holder of the Manufacturing

Authorisation and for the Qualified Person(s).

The basic concepts of Quality Management, Good Manufacturing Practice and Quality

Risk Management are inter-related. They are described here in order to emphasise their

relationships and their fundamental importance to the production and control of

medicinal products.

在产品质量/生产风险方面,应考虑采用基于风

险的预防和缓解药品短缺措施。(另请参阅第5章

有关因生产限制造成产品短缺的指导)。

The use of risk-based drug shortage prevention and mitigation activities with respect to 4

product quality/manufacturing risks should be considered. (See also Chapter 5 for 5

guidance in relation to product shortages due to manufacturing constraints.) 6

Pharmaceutical Quality System1

1.1 Quality Management is a wide-ranging concept, which covers all matters, which

individually or collectively influence the quality of a product. It is the sum total of the

organised arrangements made with the objective of ensuring that medicinal products

are of the quality required for their intended use. Quality Management therefore

incorporates Good Manufacturing Practice.

1.2 GMP applies to the lifecycle stages from the manufacture of investigational

medicinal products, technology transfer, commercial manufacturing through to product

discontinuation. However, the Pharmaceutical Quality System can extend to the

pharmaceutical development lifecycle stage as described in ICH Q10, which while

optional, should facilitate innovation and continual improvement and strengthen the

link between pharmaceutical development and manufacturing activities. ICH Q10 is

reproduced in Part III of the Guide and can be used to supplement the contents of this

chapter.

1 Article 6 of Commission Directive (EU) 2017/1572 requires Member States to ensure that manufacturers establish and implement an

effective pharmaceutical quality assurance system. The term Pharmaceutical Quality System is used in this chapter in the interests of

consistency with ICH Q10 terminology. For the purposes of this chapter these terms can be considered interchangeable.

Page 3 of 9

1.3 The size and complexity of the company’s activities should be taken into

consideration when developing a new Pharmaceutical Quality System or modifying an

existing one. The design of the system should incorporate appropriate risk management

principles including the use of appropriate tools. While some aspects of the system can

be company-wide and others site-specific, the effectiveness of the system is normally

demonstrated at the site level.

1.4 A Pharmaceutical Quality System appropriate for the manufacture of medicinal

products should ensure that:

(i) Product realisation is achieved by designing, planning, implementing,

maintaining and continuously improving a system that allows the consistent

delivery of products with appropriate quality attributes;

(ii) Product and process knowledge is managed throughout all lifecycle stages;

(iii) Medicinal products are designed and developed in a way that takes account

of the requirements of Good Manufacturing Practice;

(iv) Production and control operations are clearly specified and Good

Manufacturing Practice adopted;

(v) Managerial responsibilities are clearly specified;

(vi) Arrangements are made for the manufacture, supply and use of the correct

starting and packaging materials, the selection and monitoring of suppliers and

for verifying that each delivery is from the approved supply chain;

(vii) Processes are in place to assure the management of outsourced activities.

(viii) A state of control is established and maintained by developing and using 7

effective monitoring and control systems for process performance and product 8

quality. Quality risk management should be used in the design and 9

validation/qualification of such systems. 10 此类系统的设计与验证/确认中应使用质量风险

管理。

(ix) The results of product and processes monitoring are taken into account in

batch release, in the investigation of deviations, and, with a view to taking

preventive action to avoid potential deviations occurring in the future.

(x) All necessary controls on intermediate products, and any other in-process

controls and validations are carried out;

(xi) Continual improvement is facilitated through the implementation of

quality improvements appropriate to the current level of process and product

knowledge.

(xii) Arrangements are in place for the prospective evaluation of planned

changes and their approval prior to implementation taking into account

regulatory notification and approval where required;

(xiii) After implementation of any change, an evaluation is undertaken to

confirm the quality objectives were achieved and that there was no unintended

摘要:

展开>>

收起<<

Page1of9Chapter1:PharmaceuticalQualitySystemµÚһÕ£ºҩÎïÖÊÁ¿ÌåϵConsultationDocumentÕ÷ÇóÒâ¼û²Ý°¸Reasonsforchanges:TheGMP/GDPInspectorsWorkingGroupandthePIC/SCommitteejointlyrecommendedtoamendthetextofChapter1inordertoreflectthechangesintroducedinICHQ9(R1)onQualityRiskManagement.ÐÞ¶©ԭÒò£ºGMP/GDP¼ì²é¹¤×÷...

声明:如果您的权利被侵害,请联系我们的进行举报。

相关推荐

-

关于2020年版《中国药典》勘误的通知

2024-04-12 56

2024-04-12 56 -

《计算机化系统验证指南》VIP免费

2024-04-13 63

2024-04-13 63 -

数据完整性和合规性与药物CGMP问题与解答

2024-04-18 107

2024-04-18 107 -

新版兽药GMP条条看

2024-04-29 48

2024-04-29 48 -

2023GMP指南 质量控制实验室

2024-05-01 99

2024-05-01 99 -

药品共线生产质量风险管理指南解读VIP免费

2024-05-17 51

2024-05-17 51 -

无菌药品生产污染控制策略技术指南_征求意见稿

2024-09-14 43

2024-09-14 43 -

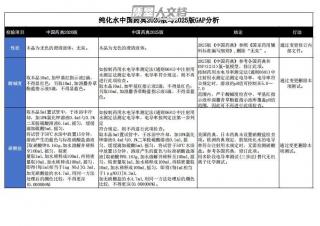

纯化水中国药典2020版与2025版GAP分析VIP免费

2025-04-18 188

2025-04-18 188 -

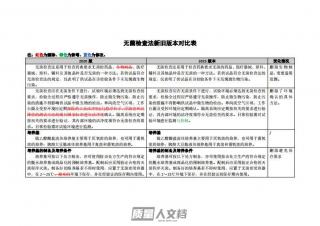

2025 无菌检查法新旧版本对比表VIP免费

2025-04-18 312

2025-04-18 312 -

1101无菌检查法对比表(2025版药典 VS 2020版药典)

2025-09-29 62

2025-09-29 62

作者:多多猪

分类:法规规范

属性:9 页

大小:395.76KB

格式:PDF

时间:2025-09-04